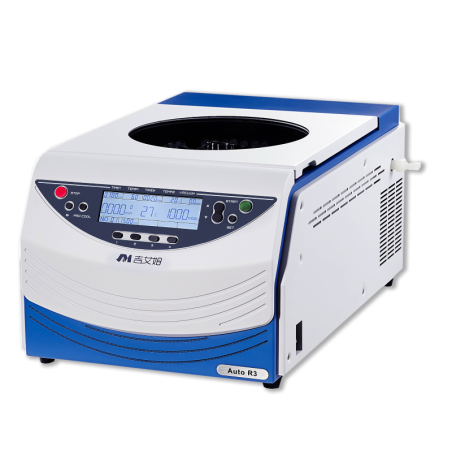

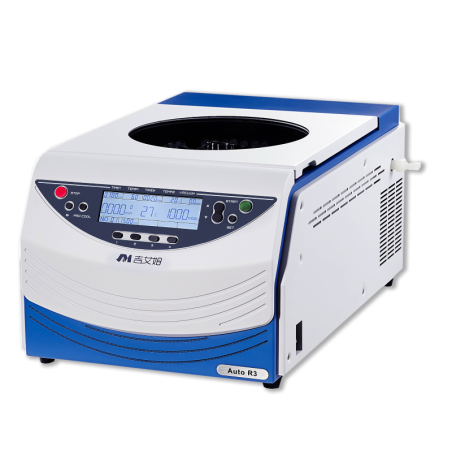

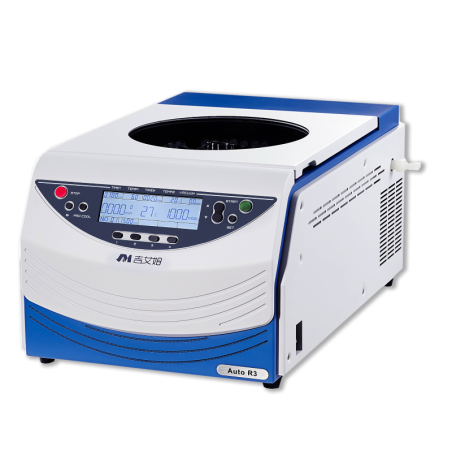

The "Auto R3 integrated centrifugal concentrator" has been designed with a customer-oriented approach, the design of the device conforms to ergonomics and features a user-friendly interface and robust durability. Comprehensive heating technology enables fast and safe concentration of DNA/RNA, oligonucleotides, proteins and other liquid samples.

Integrated Vacuum Centrifugal Concentrator Auto R3

Technical Specifications

- Speed Range: 800 rpm ~ 2000 rpm

- Maximum Centrifugal Force: 530 × g

- Time Range: 0 ~ 9999 minutes

- Temperature Control Range: Ambient Temperature + 5 ℃ ~ 100 ℃

- Temperature Control Accuracy: ≤ 1 ℃

- Pump Speed: 33 L/min

- Noise: ≤ 60 dB(A)

- Machine Power: 660 W

- Power Supply: AC 220V 50Hz / 60Hz 10A

- Dimensions (W x D x H): 608 × 370 × 299 mm

- Weight: 37.9 KG

Accessories (Optional)

- 72 x 5 ml (Round Bottom)

- 24 x 8 x 0.2 ml

- 8 x 50 ml (Conical Bottom)

- 64 x 2 ml (Sample Bottle)

- 18 x 15 ml (Conical Bottom)

- 24 x 5 ml + 66 x 1.5 ml

- 2 x 96 (ELISA) Plate

- 90 x 1.5 ml

Features

- Space-Saving: Equipped with an imported brand corrosion-resistant diaphragm pump with an integrated design.

- Ease of Use: Single-button start/stop function to prevent accidental operation.

- Corrosion-Resistant: The centrifuge chamber is treated with Teflon coating for corrosion resistance, and the vacuum pump head is made of Teflon material.

- Safe Operation: Automatically releases vacuum in case of power failure, exhaust gas evacuation function, 4 sets of program quick keys, 30 sets of user programs, two-stage temperature control design to ensure sample safety and protection, corrosion-resistant vacuum gauge, no fear of organic solvents.

Operating Principle

The Auto R3 integrated vacuum centrifugal concentrator uses high-speed centrifugal rotation technology to ensure the sample remains in the centrifuge tube without eruption. The vacuum pump creates a vacuum in the centrifuge chamber by pumping out the air. As the pressure decreases, the boiling point of the solvent also decreases. When the pressure is sufficiently low, the solvent begins to boil, and the cold trap captures the solvent vapor for condensation and recovery, ensuring the vacuum pump is not corroded by the solvent vapor. The heating pipe at the bottom of the centrifuge chamber provides heat to compensate for the heat consumed by the evaporation of the solvent and to accelerate the evaporation rate of the solvent, thus achieving the purpose of concentrating or drying the sample.

Vacuum centrifugal concentration can process dozens to hundreds of samples simultaneously without cross-contamination. The sample does not produce foam, resulting in less loss and high yield.

Application Areas

Centrifugal concentration can be performed not only at room temperature but also at low temperatures. Specifically:

- Ideal for concentrating DNA/RNA, proteins, oligonucleotides, and other liquid samples in biology and chemistry laboratories.

- Suitable for rapid and efficient evaporation of solvents in pharmaceutical research and clinical laboratories.

- Used for concentrating and drying samples in environmental analysis and other scientific research fields.

Usable Solvents

The Auto R3 integrated vacuum centrifugal concentrator is designed to be compatible with various solvents. Usable solvents include:

- Acetic Acid

- 1,2-Dichloroethane

- Methyl Tert-Butyl Ether

- Dioxane

- Methylene Chloride

- Ammonium Hydroxide

- Butanol

- IPA (Isopropyl Alcohol)

- Butyl Acetate

- Acetone

- Methanol

- Ethanol

- Isopropanol

- Water

- Dimethyl Sulfoxide (DMSO)

- Acetonitrile

- Formic Acid

- Methyl Ethyl Ketone (MEK)

- Ethyl Acetate

- Dichloromethane

- Tetrahydrofuran (THF)

- Heptane

- Toluene

- Hexane

- Benzene

These solvents are suitable for ensuring the safe and effective operation of the device. However, the use of hydrochloric acid and similar solvents is not appropriate for this device. Using the correct solvents is important to maintain the device's performance and longevity.